Contact Us

E-mail :Sale@ytc-metal.com

Phone/WhatsApp/WeChat:

+86-18233363339

Address:

No. 95, Chang'an Road, Dingzhou, Hebei Province

- Description

-

Casting process Investment casting Material GE360 Heat treatment +NT Max & Min Dimensions(mm) 245 & 4 Casting tolerance(ISO 8062-3) DCTG7 Weight(kg) 1.1 Tensile strength Rm(Mpa) ≥590 Yield strength Rp0,2(Mpa) ≥360 Elongation(%) >16 V Notch Impact testing(J) ≥20 Radiographic ASTM E446 Level2 Application industry Car

Carefully Selected Materials

Factory supply

Support customization

Careful selection

Easy to operate

Delivery on time

Perfect service

Application

Rail Transit

Boiler Equipment

Mechanical Equipment

Valves and Pipe Fittings

Shipbuilding

Electrical Hardware

Customized service

OEM/ODM

We have a professional design team that can provide full-package services from design to production. We also accept custom orders based on your drawings or samples, and can add logos or other customizations.

Non-standard custom

The source factory has deep strength, strong production and research and development ability, and can undertake the design and production of non-standard products and customized services.

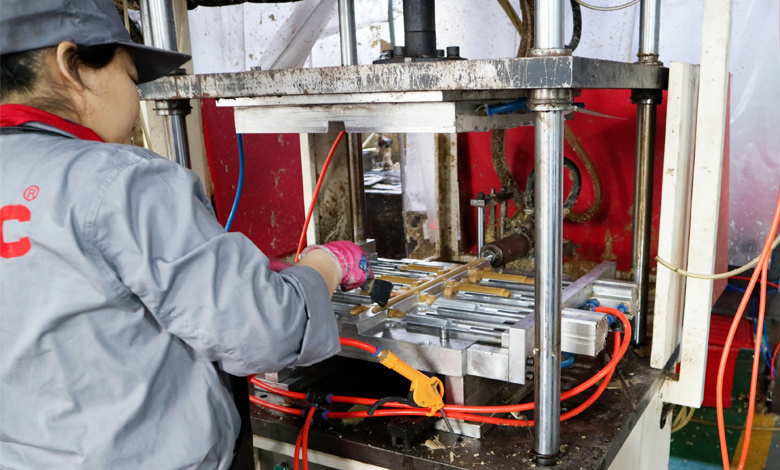

Factory scene

FAQ

How long is the production cycle?

Mold cycle 15 days, sample production cycle 15 days. Within 30 days of batch order after sample acceptance (the specific cycle is subject to product drawings and batch order quantity).

Can you assist overseas customers to purchase or outsource other products?

Yes, for other products that YTC factories cannot produce, we can provide factory audit, process supervision, product inspection, warehousing, customs declaration and other services of outsourcing manufacturers.

What are the characteristics of products produced by YTC?

YTC's products are mainly cast steel and non-ferrous metal parts, characterized:

Can be produced according to customer design drawings;

Complex design structure can achieve mass production;

Flexible material selection, available in a variety of metals and their alloys integrated manufacturing, more reliable in performance than other materials;

Due to the complex structural design, the same material is lighter than products produced by other molding processes (suitable for the automotive industry).

What should I do when there is dissatisfaction in the cooperation process or suggestions for improvement?

Please send your comments or suggestions to email: Service@ytc-maetal.com, we would like to listen to your company's suggestions for continuous improvement.

Keywords:

Get A Quote

If you need more information about our products, please feel free to contact us, we will provide you with professional service personnel, we will reply promptly after receiving the information.

Related Products